Published on September 21, 2018

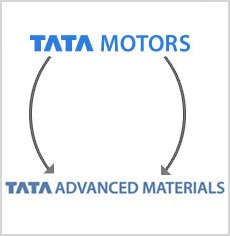

Tata Advanced Materials (TAML) attaches utmost importance to safe working practices. After the 2016 TBEM assessment, the company realised that their safety governance structure needed improvements in order to cater to their safety goals. To strengthen the company’s safety governance structure, it decided to benchmark Tata Motors’ safety governance, which is recognised as a best practice. The TAML team visited Tata Motors and studied the system. Based on the visit, TAML developed its own safety governance system, which is best suited to meet present and future safety goals of the company. The adopted governance structure is working very well since its inception.

The need

During the 2016 TBEM assessment, assessors discovered that TAML’s safety governance structure needed to be improved so that it can achieve a world-class level. As some of the assessors were from Tata Motors, the team realised that its best practice could help TAML. The TAML team visited Tata Motors Jamshedpur in February 2017 and studied the safety governance structure at the plant for two days. The Tata Motors team was very supportive and open in sharing knowledge and experience. This visit inspired TAML to adopt this best practice.

Best practice adoption

The concept of governance structure was adopted from Tata Motors but it was customised at TAML to suit the company’s needs and environment. The SHE and BE team at TAML took two months to come up with the final structure to roll out for final implementation. Various safety teams and committees were formed and employees were nominated by their functional heads. Safety training was provided to all teams. All teams and committees are headed by senior leaders of the company. The alignment and proper functioning of the whole structure took six months.

The safety governance structure comprises the Safety Apex Committee at the top and supported by various working committees — standard and procedures committee (SPC), observation and investigation committee (OIC), plant safety committee (PSC) and shop floor teams. These committees serve the below mentioned purpose:

- The Safety Apex Committee consists of TAML’s top management representatives and is responsible for the implementation of SHE policy and practices across the company. It reviews and controls the SHE performance of the company through various committees

- The SPC reviews and prepares policies, procedures and standards. The committee provides training and develops subject matter experts, takes care of training and capability development in SHE for all the employees

- The OIC prepares standards for observation and incident investigations, trains employees and implements the practice. The committee also monitors performance of the company on observation and investigation

- The standards and procedures are followed and practiced by five safety shop floor teams (SFTs). The SFT looks after implementation of SHE practices in their respective areas/departments. It is also responsible for SHE performance in their areas

- The PSC is responsible for deployment of safety practices throughout the factory as per Karnataka factory regulations. It enables horizontal deployment of practices within the SFTs.

Benefits

- With strengthened governance, each SFT organises reviews on a daily basis and owns safety observations and improvement in their area which is reported monthly to the Apex committee

- Details about unsafe practices are now quicker with increase in number of observers which has resulted in speedy action closures

- Increased awareness of employees towards safety and improvement in the safety results