Published on July 19, 2023

Elimination of manual scavenging in cleaning sewers

Context:

Tata Steel UISL (JUSCO) is engaged in collecting, treating, and managing sewage across the township. One of the major activities is waste-water treatment comprising a 550 km long circuit with more than 20000 manholes. To ensure the smooth running of the waste circuit, the manholes require regular maintenance. The conventional method required entering the manhole and clearing sewage obstruction manually in an unhygienic and inhuman environment. This initiative targets the problem of removing the human interface, which is a key challenge.

Key Challenges:

- Approach road for the vehicle due to unplanned development and encroachment

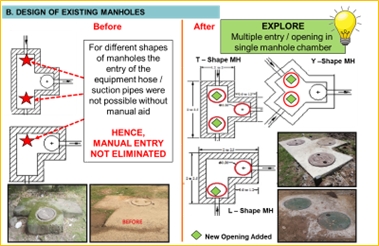

- The existing design of manholes for operations

- Manhole cleaning was man dependent, involving a risk of fatality. It involved entry into unhygienic & unsafe manholes

Our approach

A systematic approach was adopted to eliminate manual entry for manhole cleaning:

- Deploy machines like super sucker, grab desilting & power buckets

- Hand-made tools to remove big particles from a manhole, not reachable by the machine arm

- To aid removal using a grab desilting machine and super sucker, existing manholes are converted into T–shape L-shape, after dismantling and recasting of manhole top slab

- Deployment of small suction & jetting machine

- Customised small-size sewer jetting and suction machine fitted with desilting grab addressing manholes in narrow alleys

Impact:

- Hazard/risk due to entry into confined space eliminated

- Safety and quality aspect of the job enhanced, impacting the regular operational KPIs

- Health and hygiene of the workmen involved in the activity has improved

Elimination of work at a height for inspection/checking of transmission lines

Context :

Tata Steel UISL operates and maintains 20 km, 80 towers in Jamshedpur and 41 km, 167 towers in Saraikela for uninterrupted power supply 24X7 to customers. The frequency and quality of on-site proactive inspections of the transmission line conditions determine the operational performance of the transmission system. For any major abnormality, the same needs to be rectified immediately.

This initiative targets problems like working at height and inspecting transmission lines manually.

Key Challenges:

- Climbing on the tower and then visual Inspection entailed hazard of falling from the tower

- Electrocution and flashover from the live parts or due to induction

- Inspection through a thermo-vision camera from the ground level is not 100% accurate

- A major portion of the transmission line passes through the village, river, hills and forest area, and there is a limited approach

- It is time-consuming because a person has to walk through the narrow passage, climb the tower, etc.

Our approach

A systematic approach was adopted for inspecting the transmission line by deploying Thermo-vision scanning using a drone camera.

Impact:

- Hazard/risk due to working at height eliminated

- Close and accurate inspection as drone camera can reach near the insulator/conductor/jumper/tower top

- More clarity and accuracy in inspection and temperature monitoring

- Time saving, increase in productivity, quality and safety