At Tata Steel Kalinganagar (TSK), the implementation of the ‘clamshell cold cutting’ system was initiated to address the inherent risks in maintaining over 25 km of gas pipelines, which carry hazardous gases like BF gas, LD gas, and coke oven gas. ‘Clamshell cold cutting’ is a device mounted on the pipeline`s outer diameter that cuts the material with each rotation. A continuous flow of cooling liquid at the cutting point prevents overheating and spark generation. This innovative technology effectively eliminates the risks associated with hot work, making gas pipeline maintenance safer and more efficient.

Context

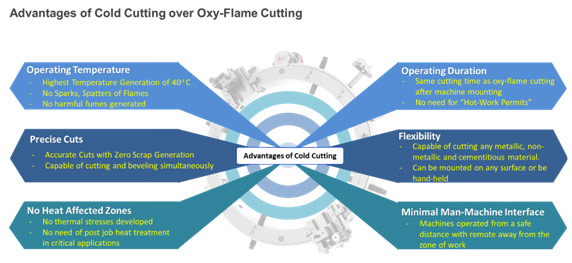

In the steel industry, the safe operation and maintenance of pipelines handling hazardous gases is crucial due to the inherent risks involved. At TSK, traditional maintenance practices like purging, using non-sparking tools, positive isolation, six-directional hazard identification & mitigation, and training have been employed. However, despite these measures, residual risks such as oxy flame cutting spatter entering gas pipelines, potentially igniting un-purged gas pockets and spontaneous combustion due to pyrophoric muck accumulation persist, posing the potential for fire or explosions. To address these risks, the TSK team sought to eliminate hot work in gas pipelines and explore flameless metal cutting solutions.

Benefits

The implementation of clamshell cold cutting has resulted in several key benefits:

- Elimination of spatter and heat: This removes the source of ignition, significantly reducing the risk of fire or explosion.

- Reduced human intervention: Remote operation minimises the need for workers to be in close proximity to the cutting operation, further enhancing safety.

- Engineering control: This approach effectively reduces risk to as low as reasonably practicable by eliminating the root cause of potential hazards.

By involving frontline supervisors, contract workers, managers, and senior leadership in brainstorming and implementing solutions, TSK has set a new standard for safe gas pipeline maintenance in the steel industry. This approach can be readily adopted by other steel companies seeking to enhance the safety of their workforce and operations.