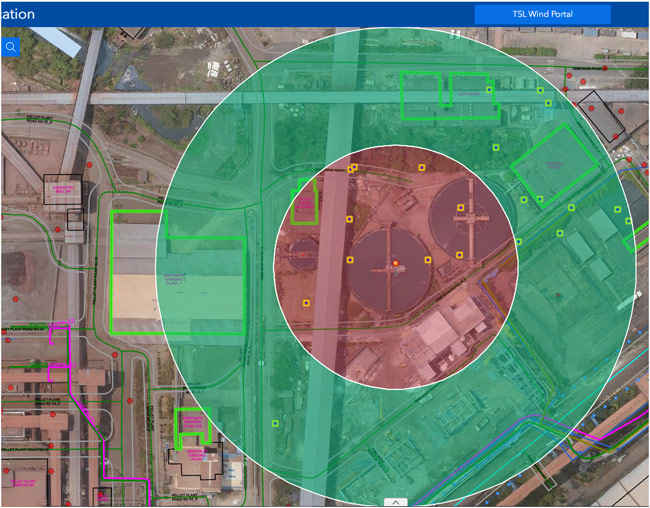

To strengthen emergency preparedness and response in the event of major gas leaks, Tata Steel developed a digital safety GIS has been developed. This system integrates dispersion modelling results with real-time visualisation capabilities to accurately identify and evacuate impacted facilities. The GIS shows the impacted facilities and generates a report containing a list of roads, buildings, and installations inside Tata Steel plants. It replaces manual plotting methods prone to errors, ensuring swift and precise response during emergencies.

Context

During toxic or flammable gas leak emergencies, identifying all the facilities impacted by the leak is crucial for effective evacuation and response. Previously, Tata Steel used to deploy manual methods for plotting impacted areas were error-prone and time-consuming. The need for a more reliable and efficient system led to the development of a digital safety GIS.

Benefits

The implementation of the digital safety GIS has resulted in significant improvements in emergency response capabilities for Tata Steel:

- It eliminates errors in determining impacted facilities and provides accurate confirmation that they have been fully evacuated during emergencies, using real-time data from the connected workforce system.

- The system has enhanced overall emergency preparedness and response for large-scale gas leaks, involving multiple departments and addressing challenges of limited visibility.

- It has been tested in mock drills, demonstrating a significant decrease in search and rescue time from 35 minutes to 16 minutes for similar scenarios.

- Employees are equipped with a ‘Suraksha Card’ that uses special beacons placed throughout the plant. These beacons transmit location data to a central system which processes and provides the real-time location of the cardholder.