Published on July 07, 2023

CHALLENGE

Since residential projects are developed in phases, various challenges are faced by the developer and the occupants who have taken possession in the earlier phases. La Vida, Gurugram is a residential development consisting of eight residential towers - six towers of G+13 storey & two towers of G+25 storey. One of the major challenges during phase-wise construction is controlling noise and dust. The project being in the Delhi NCR region only adds to the challenge from the execution point of view, especially during the winter season, as the Delhi NCR region air quality is poor and requirements of the NGT (National Green Tribunal) for construction are very stringent. For Tata Realty, the primary concern was how to address the issue of inconvenience to existing customers in the form of dust and noise.

RESOLUTION

To eliminate the dust escaping from the source, grinding machines used were with dust extractor and collector to arrest the dust at the source. Further, to control the dust from other finishing activities inside the buildings and galleries, the company explored many options of covering the individual work locations followed by covering the working floor, etc. Finally, after many deliberations and experiments at the project level, instead of covering the working floor, it was decided to install an envelope for the entire building so that the dust could be curtailed from all the finishing activities that were ongoing on multiple floors simultaneously. The building envelope will be also helpful in reducing the intensity of noise of the internal building finishing works to some extent.

Once this was decided, the challenge was to have an enveloping system which would be easy for installation, maintenance, aesthetically pleasing, not bulky, reusable, washable, and non-restrictive to the ongoing activities. Since it was decided to envelop the entire building, from a safety perspective, it was imperative that it is free from fire hazards. Needless to add, it also needed to be cost-effective.

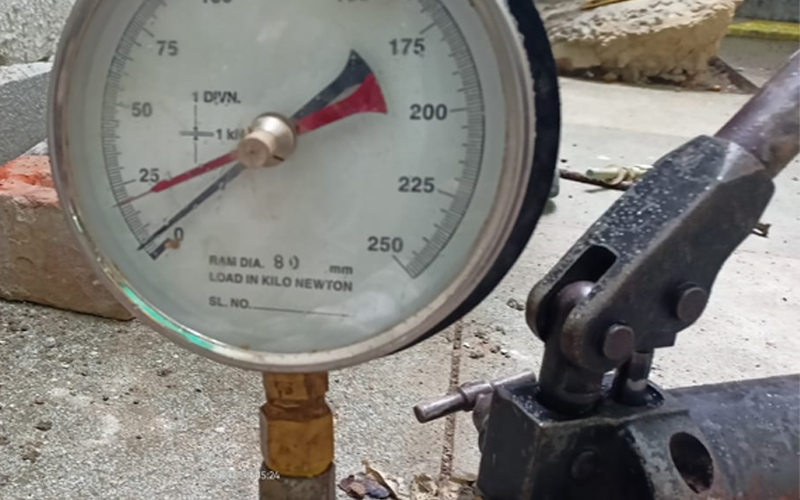

A total of four towers were installed with the building envelope, where the finishing activities were in progress, covering a total area of 53,164.38 sq meters. Random pull-out tests for the fasteners were also conducted to ensure the stability of the nets. To evaluate the fire resistance of the nets, onsite grinding was carried out at random locations, directing the sparks on the net under controlled conditions. Further, fire blankets were used for grinding work near the nets as an additional precaution measure. Building envelopes have proved to be extremely useful from a customer and an environment perspective for Tata Reality.

TECHNICAL DETAILS OF THE ENVELOPE

Wrapping of the building is done in the following way:

The material used for wrapping is a 3 layered green net having 1st and 3rd layer made of 100 gsm mono-filament dust control net, the middle sandwiched layer made of 4 mm PP rope having a mesh of size 100 mm x 100 mm, and the outer rope to hold the net is of 12 mm PP rope. All this is attached with ropes at the edge with the structure at 1.5 m centre to centre with the help of fasteners.

To hold the net in place, 3 types of fasteners are used, which are 8 mm x 75 mm, 10 mm x 125 mm and 12 mm x 150 mm, to give proper anchorage and support to the entire system.