Tata AutoComp reported a reduction in reportable & non-reportable accident numbers in FY2023-24 owing to consistent efforts to encourage small improvements in plants and work-stations. The improvements helped reduce unsafe acts and conditions and near-miss incidents, resulting in a positive impact on the company’s overall Health, Safety and Environment performance.

This outcome can be traced to the company’s keen focus and proactive approach on increasing safe behaviour by observing employees’ actions and analysing the consequences that follow. It aims to reduce hazards, risks, and incidents by reinforcing desired behaviours. It believes that small improvements and changes can help nurture a safety culture besides encouraging trust and cooperation between leaders and employees. Employees become more observant of their own actions, leading to improved safety. This also leads to long-term solutions for eliminating risks and hazards.

Towards this end, the company motivates its employees to participate in various competitions and industry platforms such as the QCFI Kaizen and CII National Kaizen competitions. This not only boosts their morale but also instils confidence in making presentations to industry leaders.

Purpose

Improvement in safety culture and boosting employee morale

Methodology

- Conducted focused safety walks and surprise safety walks across all plant locations

- Adopted Tata Safety & Health Management System (TSHMS) along with half-yearly internal TSHMS safety audits by certified assessors

- Encouraged employees to pursue self-paced e-learning courses on safety topics to enhance their interest in the subject

- Business unit (BU) safety assessments conducted by cross-BU safety officers to identify and close the opportunities for improvement

- Total Quality Management (TQM) and Tata Business Excellence Model (TBEM) approach helping to improve the company’s existing safety culture

Key Takeaways

- A large number of BUs and employees are taking part in various forums to showcase their safety improvements and initiatives

- Employees are taking the lead in observing processes closely, thereby focusing on small improvements

- Increased ownership and sense of belonging

- As a leader of small representing forum employees are being appreciated

- Learning and knowledge-sharing from various participating industries

Benefits

- Small Poka-yoke helps in reducing unsafe acts/unsafe conditions and near-miss incidents

- Boosts morale of employees and contractors working on the equipment

- Positive reinforcement in safety culture to the relief of line supervisors and managers

- As safety improves, productivity increases and, in turn, the quality of work improves

- Area ownership has increased

Some examples of Improvements

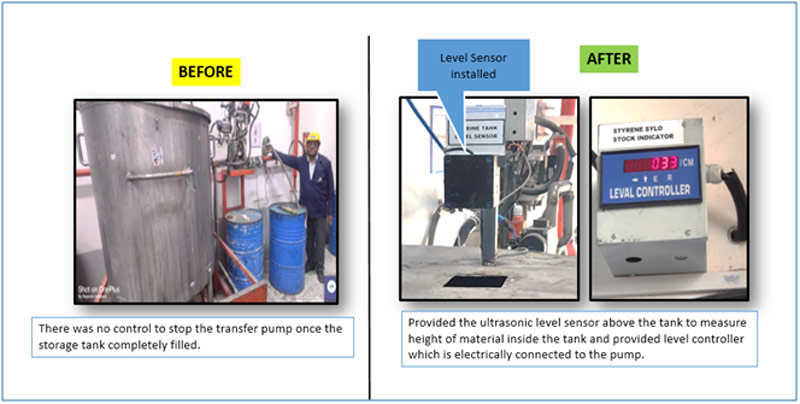

1. Tata AutoComp’s Composite Division team won a Silver award at the 48th CII National Kaizen Competition 2024 for installing a UV-level sensor to prevent any chemical spills from its storage tanks.

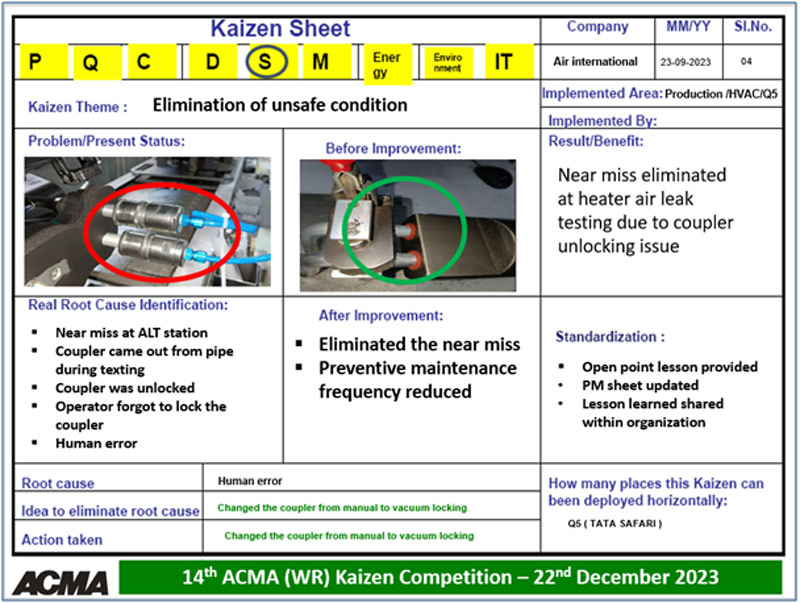

2. Tata AutoComp’s Air International team won four Gold Awards and two Silver Awards in the Best Safety Kaizen category at the QCFI Kaizen Competition, Pune Chapter, held on January 19, 2024. The award was won for modifying a manual coupler locking into a vacuum locking.

3. Tata AutoComp’s Interiors and Plastics Division from the Ranjangoan Plant won the third prize at the Narayan Meghaji Lokhande Safety and Health Awards 2023 for demonstrating good work on Industrial Safety and Health. The Government of Maharashtra’s Labour Ministry and Directorate of Industrial Safety and Health organised the state-level safety competition in April 2023.

4. Tata Toyo Radiator won the prestigious Safe India Hero Plus award for best fire and safety practices at the Bharat Safety Yatra held at Buntara Bhavan, Baner, in Pune on January 29, 2024. The event was attended by officials from the Directorate of Industrial Safety and Health and fire brigades in Pune region as well as by industry leaders and safety professionals. The Safety Yatra felicitated safety and fire heroes from both the government and private sectors.

5. Tata AutoComp Hendrickson Suspension received the Platinum award in the Innovative Kaizen category at the 46th CII National Kaizen Competition held in July 2023. The award was won for ensuring safe working conditions while torqueing a 12.5-tonne lift axle assembly.